When I started on this venture I didn't REALLY know what I was doing. I know electric fuel pumps and fuel systems, but not THIS one, which caused me to make a few mistakes. These pictures do not show all of the mistakes, just the mis-mounting of the fuel pump. It didn't have to be moved far, but I found it is much tighter in there than I first expected since my truck is a short-bed, 4x4.

Due to the inherent fuel pump problems on the 24v Cummins engines in the Dodge trucks, I decided to fix the problem myself instead of messing with getting the fuel pump replaced repeatedly until the warranty runs out. The solution I came up with includes a Holley electric fuel pump new steel-braided fuel lines, and the necessary wiring for the fuel pump.

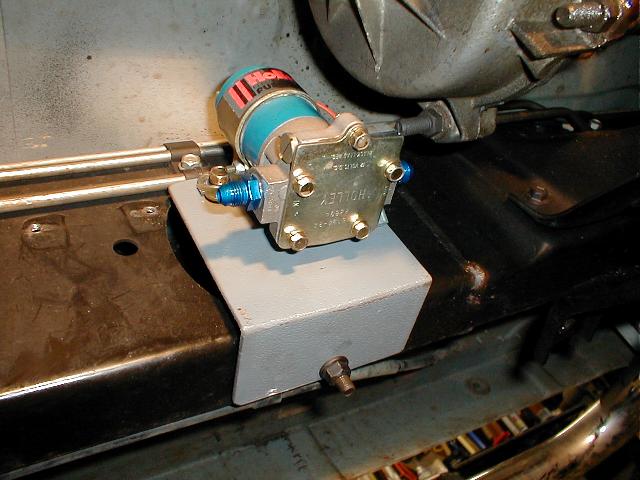

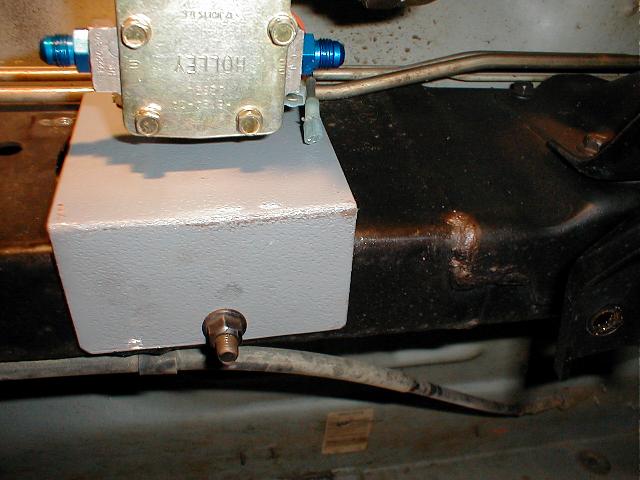

The installation was relatively easy, probably the hardest part was creating the bracket. The bracket is just a piece of 1/8" plate, which I grooved with a grinder at the location where I wanted to bend it, then bent it by hitting it with a hammer while it was mounted in a vice. Once I had the 90 degree elbow in it, I welded the inside of the elbow joint (that groove I created was handy for this also) then painted it.

I did a little twist to my fuel pump replacement. I planned it and installed it in such a way that I could remove the entire assembly and go back to the original fuel delivery system if I ever needed to, such as for warranty issue, or if my aftermarket fuel pump dies on the road some place. I will need a 17mm wrench or socket and a screwdriver to switch it back over in an emergency.

I got a Holley Blue fuel pump. The specs say it has good flow and pressures of around 14.5-15 PSI. Mine does not have that high a pressure, but the 11-12 PSI is OK. As Holley is having some quality control issues, I cannot recommend their pumps at this time. The one I purchased was NOS from Ebay, so mine was not affected by this problem. If it ever fails I will go with Product Engineering's PE4200 pump. I have heard nothing but good things about this pump from a lot of people. One guy who I know is running Super Mental injectors and somewhere over 500 HP, is running it and says his fuel pressure always stays at 16 PSI, whether idling or running WOT. THAT is impressive!

The Product Engineering pump is available from sources such as Advanced Diesel Technology.

In my efforts to make this a reversible thing, I decided to do things different. First of all, it is my understanding that the fuel pump wiring gets it juice directly from the computer. I did not want to overtax the computer wiring since the fuel pump was being located further away than the original wiring was planned for. To remedy this, I bought a universal relay that would handle 25 amps. This was a Standard brand relay, but you could use anything. I just like that this one had its own onboard fuse.

I still wanted to use the original wiring from the fuel pump, because the computer controls it. What advantage that gives me is the fuel pump not running when the truck is not running. This is a safety thing since if I am in a wreck or something and the motor stops, I will not have the fuel pump continue to pump fuel in the event there is a fuel line leak caused by the wreck.

To facilitate this, I purchased the little pigtail you need for the newer style fuel pumps Cummins came out with, that are supposed to be better, but appear to only have a different plug, so an adapter pigtail is required. I just installed the pig tail to the original Dodge wiring harness and cut the other end to go to my fuel pump relay. This pigtail is Cummins part number: 4025182.

Since I was replacing the fuel lines with larger ones, I just left the old ones in place and routed the new ones beside, or near, the old ones. At the fuel tank I unplugged the fuel pick-up hose and put a corner of a zip-lock freezer bag (heaviest plastic bag I had handy) over it with a rubber band to keep dirt out. The new hose went in its place on the fuel tank. Next, at the fuel filter end, I removed the banjo bolt, and loosened it where it connects to the fuel pump. After removing the banjo bolt and storing it in the truck, with its gaskets, I shifted the old line off the to driver's side a little, but still sitting over the fuel filter housing, then tightened the connection to the fuel pump back up. This is a steel line and is stiff so it will stay where I tightened it on the fuel line. I also covered this line with a zip-lock freezer bag and a rubber band. If, at some point, I need to revert back to my old fuel system I can just remove my aftermarket hose on both ends and plug in, or replace the banjo bolt in its original location Remember it's stored in the truck in case it is needed). Now, in my case the stock fuel pump is still good, or at least it was when I did this. Since these fuel pumps are known for their problems, there is no guarantee that my little twist to this installation will pay off when I need it, but I did it anyway.

The pump works great. I can hear it just a little when I turn the ignition on, but I cannot hear it at all when the engine it running. One thing to be said for the noise of the Cummins? The fuel pressure is 11-12 psi key-on, engine off, and when idling. 9-10 psi at cruise and no lower than 8 psi at WOT.

I originally mounted the fuel pump closer to the tank but moved it. I started with 3/8 fuel hose, but decided I did not like the way it was done and wanted better. The new lines I got are larger and more durable, but they cost about 300.00 and required moving the fuel pump forward a little. I got them from Advanced Diesel Technology. ADT told me I could have built them myself, but I figured I'd let them to the dirty work since they already knew the necessary lengths required.

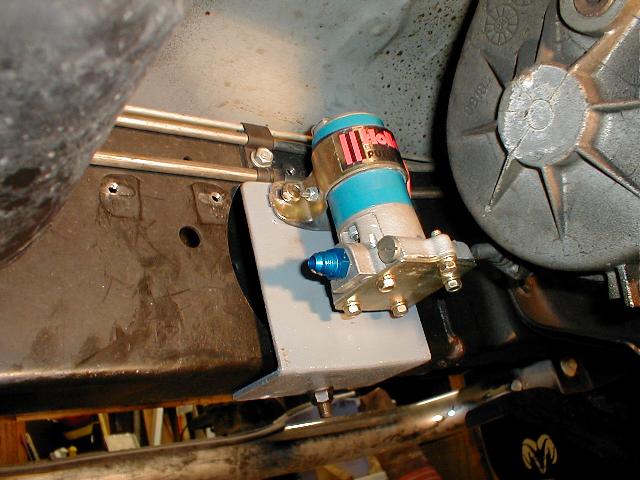

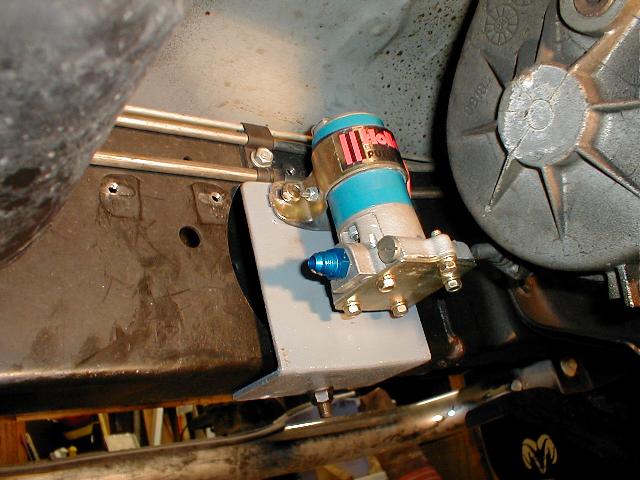

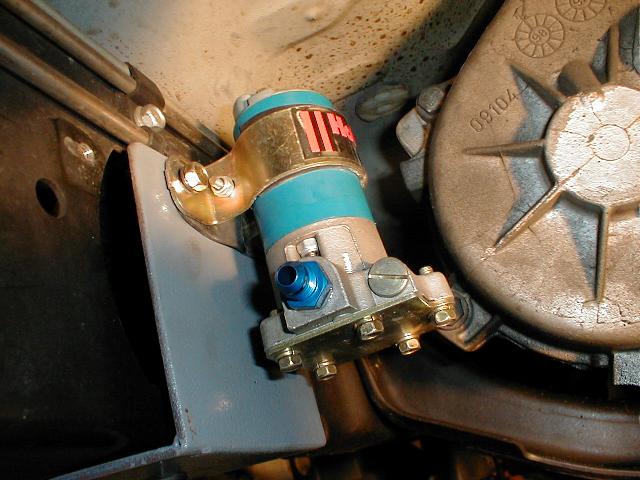

The new fuel pump mounting location, putting it on the bracket, before putting skid plate support back up, hooking up wires and fuel lines.

Another

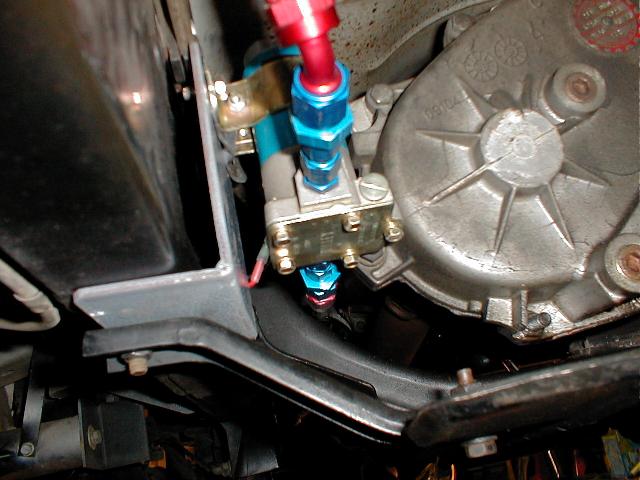

This picture shows the approximately 1/8 inch clearance between the fuel pump and the transfer case stud.

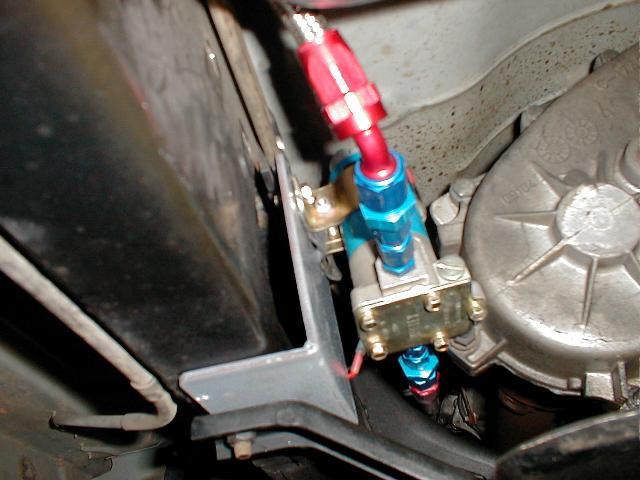

Another view of the proximity of the fuel pump to the transfer case.

All fuel lines and wires connected, skid plate back on. Ready to go, on this end.

The fuel lines going into and coming out of the fuel filter housing.

Where the fuel line goes into the VP44 injector pump.